The installation technical of the cable bolt is very important, as a manufacturer of cable bolt, I will lead you to see the relevant requirements of cable bolt construction today.

1. Formation hole

The anchor cable adopts the YXZ-70 professional anchor drilling rig to drive the eccentric DTH hammer and the casing to drill holes with a high air pressure air compressor, the diameter of the hole is 150mm. When the cable bolt is formed into a hole, pay attention to controlling the inclination angle of the cable bolt, after the hole is formed, check the hole depth, the hole diameter and the inclination angle, and make a construction record and concealed engineering inspection record.

2. Cable bolt body placement

When the cable bolt is made, it should be 1.0~1.5m longer than the design to meet the locking needs, the positioning frame spacing is 1.0m, and the steel wire is evenly bundled around the steel strand, the secondary grouting pipe is fixed to the center of the positioning skeleton. In the free section of the cable bolt, the steel strand is covered with butter and wrapped in a plastic sleeve to ensure that the strand is separated from the cement slurry. Slowing put the fabricated rod and secondary grouting pipe into the cable bolt hole.

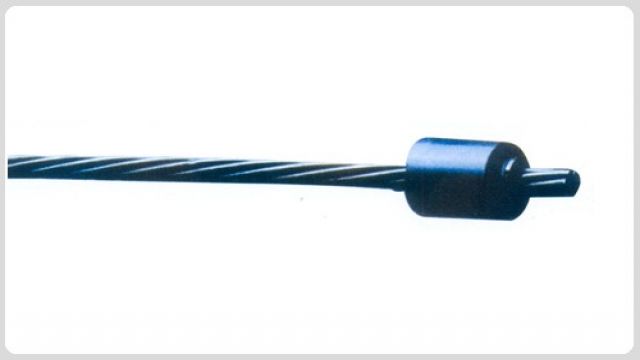

3. Anchor head

The

anchor head of the cable bolt is composed of steel backing plate and

reinforcing steel mesh and anchor. Steel backing plate made of 20mm thick steel

plate in processing factory. The size of the pad is 300*300mm, a circular hole

of Φ80mm

is drilled in the middle of the backing plate, and the steel backing plate is

bonded with M30 mortar after the flat pile is cut.

Cable bolt is a kind of mainly support product in our company, Zongxiang can provide you rock bolt, wire mesh, steel arch, etc. All used for mine and tunnle. High quality products and professional service for you. Contact us as the following.

Email: zxminesupport@zxsteelgroup.com

WhatsApp: +86 18236766038

PREVIOUS POST

Three methods of anchor corrosion protectionGet the Price

Online Chat

To top