The mining industry relies heavily on effective ground control to ensure the safety and efficiency of operations. One of the critical components in maintaining ground stability in coal mines is the use of split set stabilizers, also known as friction stabilizers. An essential accessory for these stabilizers is the anchor plate, which plays a pivotal role in distributing load and securing the stabilizer in place.

Split Set Stabilizers Overview

Split set stabilizers are a type of ground support used widely in mining and tunneling operations. They are long, slotted steel tubes that are driven into a pre-drilled hole. The primary function of these stabilizers is to provide immediate frictional resistance between the rock and the steel tube, thereby stabilizing the surrounding rock mass.

Function and Importance of Anchor Plates

Anchor plates are steel plates placed at the mouth of the borehole, through which the split set stabilizer is driven. Their primary functions include:

Load Distribution: Anchor plates distribute the load applied to the stabilizer over a larger area of the rock face, preventing localized failure around the borehole.

Enhanced Stability: By providing a larger surface area for load transfer, anchor plates enhance the overall stability of the installed split set system.

Preventing Back-Out: They help prevent the split set stabilizer from sliding out of the borehole under dynamic loading conditions, which is critical in the seismic-prone environments of underground coal mines.

Surface Control: Anchor plates help control small rock fragments and loose material on the surface of the excavation, which can pose a hazard if not properly managed.

Design and Material

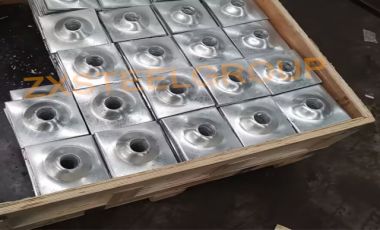

Anchor plates are typically made of high-strength steel to withstand the harsh underground conditions and the significant loads applied during mining operations. Key design considerations include:

Size and Shape: The size and shape of the anchor plate are crucial. Common shapes include square, rectangular, and circular, with sizes varying based on the specific requirements of the mine. The plate should be large enough to distribute loads effectively but also compatible with the available installation equipment and space constraints.

Thickness: The thickness of the plate is also important, as it must be robust enough to resist deformation under high loads. Typical thicknesses range from 6mm to 12mm, depending on the expected load and ground conditions.

Corrosion Resistance: In the corrosive environments of coal mines, anchor plates are often coated or made from corrosion-resistant materials to prolong their service life.

Installation Process

The installation of anchor plates in conjunction with split set stabilizers involves several steps:

Drilling: A hole is drilled into the rock face, typically slightly smaller than the diameter of the split set stabilizer to ensure a tight fit.

Positioning the Plate: The anchor plate is placed over the mouth of the borehole.

Driving the Stabilizer: The split set stabilizer is driven through the anchor plate into the borehole using a specialized installation tool. As the stabilizer is driven in, it expands radially and grips the rock tightly.

Securing the Plate: Once the stabilizer is fully installed, the anchor plate is secured against the rock face, providing immediate load distribution and enhancing ground support.

Applications in Coal Mines

In coal mines, the use of anchor plates with split set stabilizers is particularly important due to the inherently unstable nature of coal seams and surrounding strata. They are used in various applications, including:

Roof Support: To prevent roof falls and ensure the safety of underground personnel.

Rib Support: To stabilize the sidewalls (ribs) of coal seams.

Longwall Mining: In longwall mining operations, where large sections of the coal seam are removed, anchor plates help maintain the integrity of the surrounding rock.

Anchor plates are a vital component in the use of split set stabilizers for ground control in coal mines. By distributing loads, enhancing stability, and preventing stabilizer back-out, they contribute significantly to the safety and efficiency of mining operations. Proper design, material selection, and installation of anchor plates are essential to maximize their effectiveness and ensure the long-term stability of underground excavations.

Address: No. 1738, 17th Floor, No. 1 Mall, Shangdu Road, Zhengdong New District, Zhengzhou City, Henan Province, China

Email: zxminesupport@zxsteelgroup.com

Tel: +86-199 3712 3680

© 2020 ZXSTEELGROUP