Anchoring technology originated from roadway support in mines, and has been widely used not only in major coal-producing countries, but also in metallurgy, water conservancy and hydropower, railway, highway, military industry, construction and other projects. Among them, split bolt is widely used due to its simple and convenient installation, large anchorage force and other characteristics.

In order to facilitate the future use of split bolt, today we specially explain the construction steps of split bolt, welcome everyone to watch!

(1) Positioning: After the excavation section is inspected and qualified, the bolt vacancy is marked on the rock face according to the design requirements;

(2) Manual hand - held pneumatic drill is used to make holes in the excavation guide pit. Technical requirements for hole making: the opening deviation is less than 2%, and the hole depth is 3-5cm longer than the insert part of the bolt;

(3) Slowly insert the bolt 3-5cm from the bottom of the hole. After the rod body is inserted, close the orifice with cement mortar in time, and even the vent hole;

(4) Rock bolt grouting: The grouting pressure should be adjusted to 0.5-0.8mpa to allow grout to be injected slowly. When grout flows out of the vent, close the vent and stop grouting after 3-5 minutes of steady pressure injection.

(5) Installation of pressure pad and nut. After grouting, add pad and nut at the end of the rock bolt rod. At this time, no fastening is required. After 24 hours of grouting, tighten the nut with a fastening force of 10kn/m-20kn/m.

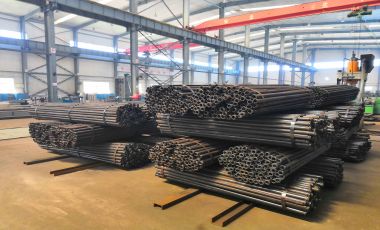

Zongxiang Steel Group can provide you safe and reliable split bolt. If you have any needs about our support products, pls contact us for a quote.

Email: zxminesupport@zxsteelgroup.com

Whatsapp: +86 18236766038

Address: No. 1738, 17th Floor, No. 1 Mall, Shangdu Road, Zhengdong New District, Zhengzhou City, Henan Province, China

Email: zxminesupport@zxsteelgroup.com

Tel: +86-199 3712 3680

© 2020 ZXSTEELGROUP