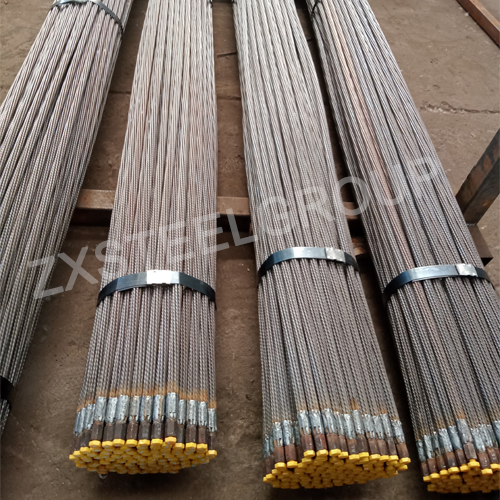

1. Mechanical expansion shell end anchoring is used to solve the problem of mismatch between the three diameters of large-aperture resin anchors. It is tensioned and pre-tightened. The anchor cable is loaded immediately after installation, and the pre-tightening force exceeds 200KN.

2. The cable body is a hollow structure with its own grouting core pipe. Reverse grouting is used to inject cement slurry or chemical slurry into the borehole to achieve full-length anchoring of the anchor cable and grouting reinforcement of the surrounding rock.

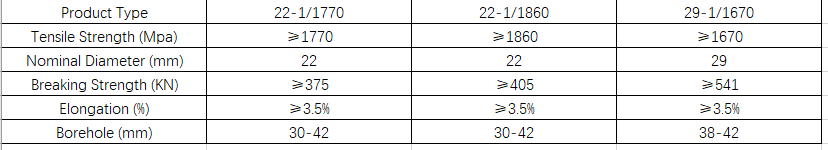

3. The cable body is processed with high-strength spiral rib steel wire, which improves the surface roughness of the cable body, increases the anchoring force and load transfer characteristics of the anchor cable, and improves the support stiffness.

4. The tail of the cable body is equipped with a grouting joint, which can be directly connected to the grouting pump for high-pressure grouting, eliminating the complex process of tying grouting pipes and exhaust pipes on site, greatly simplifying the construction process.

5. It realizes the integration of anchoring and grouting in large holes, and the cable structure can realize high-pressure grouting, improving the anchoring performance and grouting effect of the anchor cable.

If you have any question, please do not hesitate to send us a message

Address: No. 1738, 17th Floor, No. 1 Mall, Shangdu Road, Zhengdong New District, Zhengzhou City, Henan Province, China

Email: zxminesupport@zxsteelgroup.com

Tel: +86-199 3712 3680

© 2020 ZXSTEELGROUP