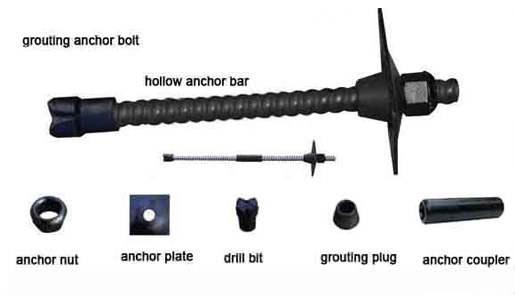

The self-drilling hollow bar anchor system consists of a hollow threaded bar with an attached drill bit that can perform drilling, anchoring and grouting in a single operation. The hollow bar allows air and water to freely pass through the bar during drilling to remove debris and then allow grout to be injected immediately after drilling is completed. Grout fills the hollow bar and completely covers the entire bolt. Couplings can be used to join hollow bars and extend the bolt length while nuts and plates are used to provide the required tension.

Material: S45C, 40Cr

Component:

The main feature of the Self-Drilling Anchor (SDA) system is the application of a single-use drill bit in combination with the rock bolt being used as a drill steel. Thus, the rock bolt is connected to the hydraulic rock drill by an adapter device and installed in the way a conventional borehole is drilled. The SDA program consists of the following:

> Single-use drill bits, which are available either hardened or with carbide inserts

> Hollow, steel bars, with a continuous outside thread

> Steel couplings, with a continuous inside thread

> Steel nuts

> Steel face plates

The bolts are classified according to thread type and material:

R-type has a rope thread, and is available in sizes from R25 to R51.

T-type is according to international standard, and is available in sizes from T30 to T103.

FRP bolts are made

out of fiberglass and are available from S15 to SXX in both solid and hollow

versions

Specification:

|

Product data sheet |

||||

|

Hollow Anchor Bar |

||||

|

Size |

Outer Dia.(mm) |

Ultimate Load(kN) |

Yield Load(kN) |

Weight(kg/pc) |

|

R32N |

32 |

280 |

200 |

3.5 |

|

R32N1 |

32 |

320 |

220 |

4.1 |

|

R38L |

38 |

400 |

280 |

5 |

|

T40L |

40 |

440 |

320 |

6 |

|

Coupler |

||||

|

Size |

Outer Dia.(mm) |

Length(mm) |

Weight(kg/pc) |

|

|

R32 |

44 |

150 |

0.94 |

|

|

R38 |

51 |

160 |

1.34 |

|

|

T40 |

54 |

140 |

1.14 |

|

|

Hex Nut |

||||

|

Size |

Outer Dia.(mm) |

Length(mm) |

Weight(kg/pc) |

|

|

R32 |

50 |

70 |

0.8 |

|

|

R38 |

60 |

80 |

1.36 |

|

|

T40 |

65 |

50 |

0.94 |

|

|

Plate |

||||

|

Size |

Outer Dia.(mm) |

Ultimate Load(kN) |

Yield Load(kN) |

Weight(kg/pc) |

|

R32N |

32 |

280 |

200 |

3.5 |

|

R32N1 |

32 |

320 |

220 |

4.1 |

|

R38L |

38 |

400 |

280 |

5 |

|

T40L |

40 |

440 |

320 |

6 |

Applications

The SDA system is suitable for simultaneous drilling and grouting in different applications:

|

Tunnelling and mining: |

Ground Engineering: |

|

Radial bolting |

Ground consolidation and injection |

|

Spiling |

Soil nailing |

|

Face stabilisation |

Slope stabilisation |

|

Portal preparation |

Microinjection pile |

|

|

Temporary support anchoring |

Features and Advantages

Particularly suitable for difficult ground conditions.

An efficient installation since drilling, placing and grouting can be performed in a single operation, saving both time and money.

Self-drilling system eliminates the requirement for a cased borehole in collapsing soils.

Fast, single-step anchoring system with simple equipment able to work with standard track drill (top hammer) or hand-held drilling equipment, eliminating the need for larger casing rigs.

Installation with simultaneous drilling and grouting possible, and post grouting system is simple.

Continuously drilling and grouting under high pressure causes the grout to permeate into looser soils and creates a bulb-effect for increased bond capacity.

Easy installation in all directions, also upwards, and similar installation methods for all ground conditions.

Suitable for working in limited space, height and in areas of difficult access.

Galvanizing for enhanced corrosion protection is available if necessary.

Multiple ranges of drill bits suitable for different ground conditions.

Continuously threaded bar pattern can be cut and coupled anywhere along its length to achieve all lengths.

If you have any question, please do not hesitate to send us a message

Address: No. 1738, 17th Floor, No. 1 Mall, Shangdu Road, Zhengdong New District, Zhengzhou City, Henan Province, China

Email: zxminesupport@zxsteelgroup.com

Tel: +86-199 3712 3680

© 2020 ZXSTEELGROUP